Jacket Pot

Industrial Jacketed Cooking Pot Kettle

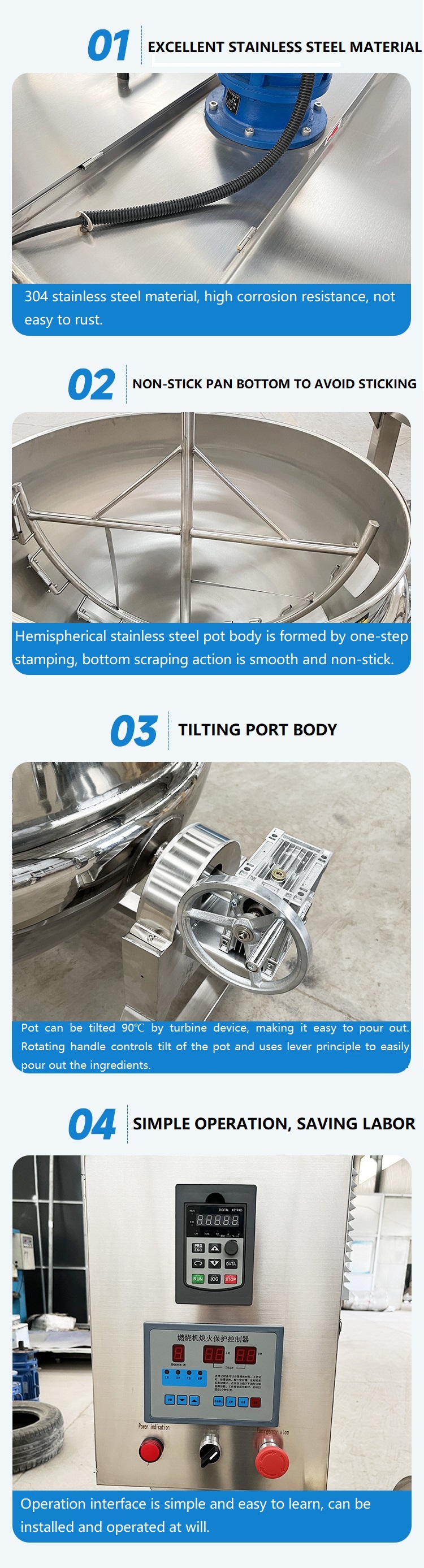

※ The inner pot of cooking kettle is 4mm, outer pot is 3mm, material is SUS304.

※ The insulation layer uses aluminum silicate insulation, which has good insulation effect and is not hot.

※ The temperature controller uses full digital display, which is easy to operate, accurate in control, and fully automatic.

※ Leakage protection switch is used for safe operation.

※ Independent distribution box device.

FOBQINGDAO price: USD2000-USD4000/SET

Pls contact us for accurate price.

Product Details

Industrial Jacketed Cooking Pot Kettle

Product Description

Double jacketed steam kettle is widely used in processing of candy, pharmaceuticals, dairy products, alcohol, cakes, preserves, beverages, canned food, stewed food and other foods. It can also be used in large restaurants or canteens to make soup, cook vegetables, stew meat, cook porridge, etc. It is a good equipment for improving quality, shortening time and improving working conditions of food processing.

Equipment Feature

※The stirring teeth are made of high-temperature resistant polytetrafluoroethylene plates, which have strong corrosion resistance, high temperature resistance, high lubrication, non-adhesion, and non-toxicity. They are used for conveying and operating viscous materials which have strict hygiene requirements such as food, beverage and other processing and production departments.

※Stirring teeth are removable, making cleaning more convenient.

※Industrial steam jacketed kettle uses a new horizontal turbine reducer, which is quiet, stable and beautiful.

※Pot flipping system: the whole pot is manually flipped and discharged through worm gear and worm, which is stable and reliable, can be tilted at 90°, easy to clean, reduces labor intensity.

※Steering handle is light in reversing and rotation, equipped with a positioning device for accurate positioning.

※Electric heating, thermal oil, gas, steam heating and other heating methods are available for customers to choose. Heating area is large and thermal efficiency is high, which is suitable for temperature and heating rate requirements of different functional materials.

※Stirring method adopts axial bottom scraping stirring to ensure that there is no dead corner in pot.

Jacket Kettle Classification

1. According to structural form, it can be divided into: tilting jacket pot, vertical (fixed) jacket pot.

2. According to heating method, it can be divided into: electric heating jacket pot, steam heating jacket pot, gas heating jacket pot, electromagnetic heating jacket pot.

3. According to process requirements, it can be divided into: jacket pot with stirring and jacket pot without stirring.

4. According to sealing method, it can be divided into: uncovered jacket pot and flat-covered jacket pot.

Product Structure

Steam jacketed cooker is a series of products, mainly composed of pot body, jacket, tilting, stirring and frame. The pot body of jacketed cooking kettle is stamped and formed in one time, inner and outer pot bodies are welded, both made of SUS304 stainless steel. The middle layer is connected to heat transfer oil and gas furnace plate.

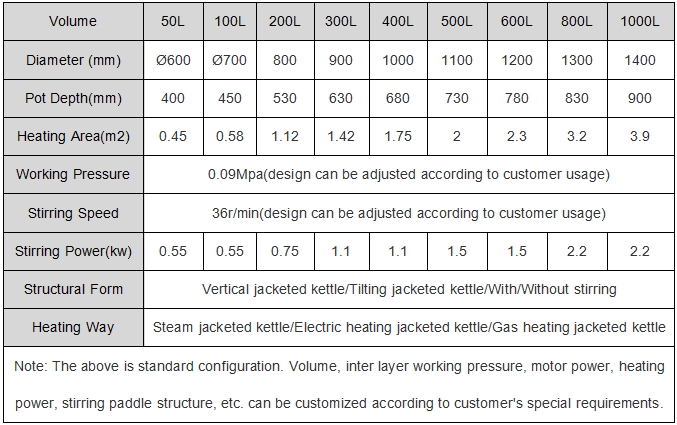

Technical Parameters

Remarks:more models pls contact us for customized.

More Details Show

Is Not You Want? Click Here

Multifunctional Vegetable Slicer Machine

Apple Peeler Corer Slicer Machine

Commercial Double Head Vegetable Cutting Machine

Automatic Dumpling Samosa Making Machine

Contact Info

HENAN LOFTY MACHINERY CO.,LTD

Email: info@loftymachinery.com

Website: www.loftymachinery.com

Contact Person: Erie Li

Whatsapp/Mobile:+8613619848687

8613619848687

8613619848687